Sorting & Scanning Recycling At Scale

Sortation

at scale

Learn how Polytag work with Pellenc ST to combine near infra-red AI and UV tags to introduce the next generation of sortation at scale.

We’ve combined Polytag’s UV tags and Pellenc ST’s near infra-red AI.

This fusion of technologies allows for a dual-sorting process never seen before.

Polytag and Pellenc ST collaborate in a non-exclusive open source approach.

Polytag and Pellenc ST: Closing the Value gap

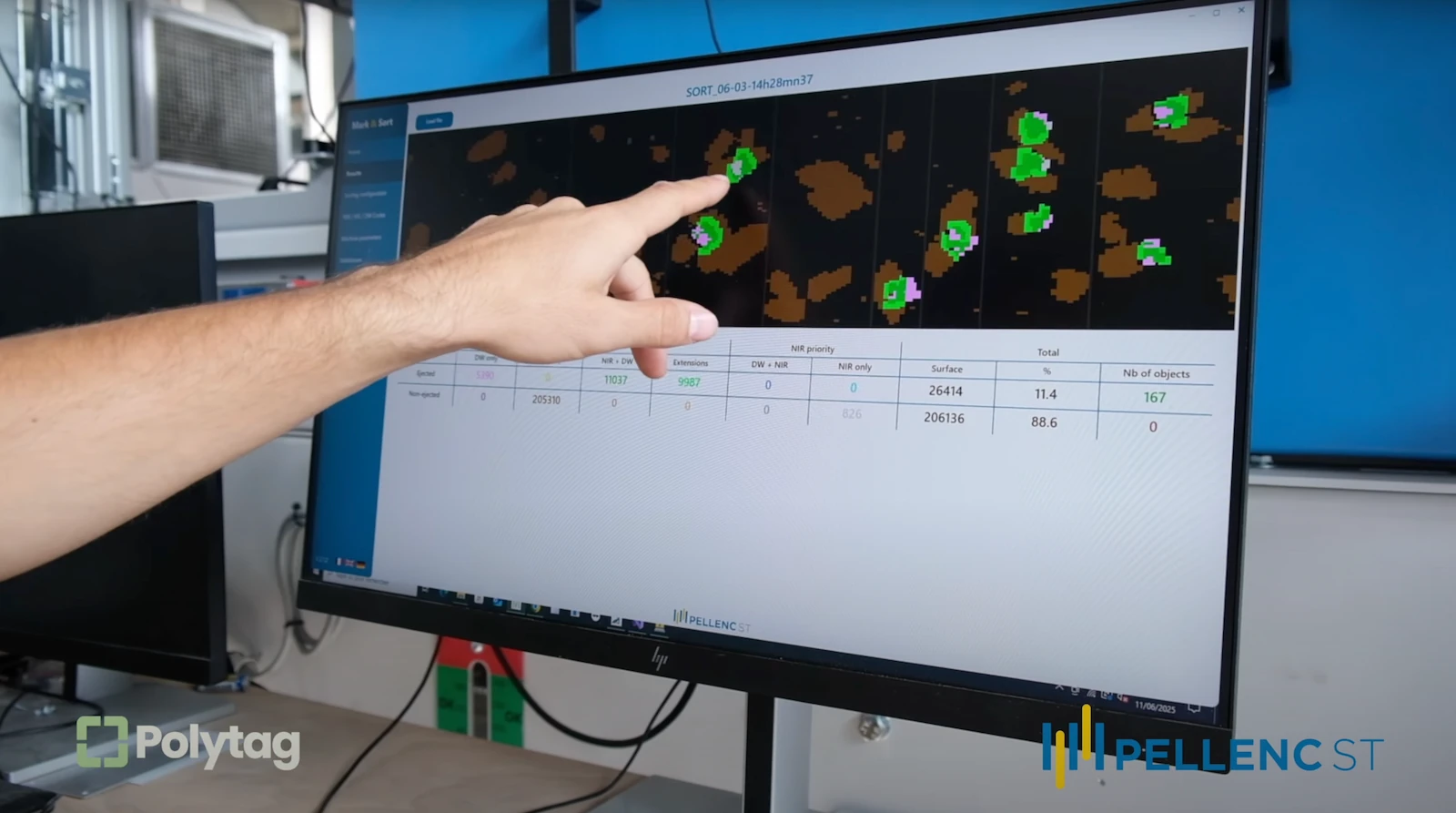

By combining Pellenc ST’s expertise in sensor-based sorting with Polytag’s data management, the partnership enables real-time tracking and optimisation of packaging waste through the recycling process from MRF to Recyclers. Each packaging item is embedded with invisible printed UV tags, in the form of a GS1 open standard data matrices. As an item enters the recycling stream, a detection unit instantly captures its associated data.

The system executes precise sorting actions based on near-infrared (NIR) spectroscopy and data embedded in the UV tags. Now, the industry can now get real-time, barcode-level data on the journey of each item and sort it into more valuable bales of recyclable material.

This information shows when, where, and how much packaging is being recycled. The accuracy of this data empowers companies to meet strict Extended Producer Responsibility (EPR) regulations, verify sustainability claims with hard evidence, and make data-backed decisions.

Polytag Pellenc ST Partnership 2025

Learn more about the collaboration between Polytag and Pellenc ST in this interview with Alice Rackley, CEO of Polytag.

Unprecedented Visibility Into Your Recycling Journey

This non-exclusive partnership between Polytag and Pellenc ST provides recycling facilities with powerful new capabilities to detect and sort waste streams. By embedding smart data at barcode level directly into packaging materials, the collaboration empowers waste management companies and brand owners with unprecedented control of the recycling journey of their products, ensuring that more packaging stays within the circular economy.

Why is this important? Downcycling. The hard truth about plastic recycling is that it’s often a process of catastrophic value loss. A high-performance plastic bottle, which costs £1,500 per tonne as a virgin material, can plummet to just £150 per tonne after a single use. That’s a staggering 90% depreciation. Without smart sortation, a virgin plastic bottle becomes a lower-grade item like a fleece or a park bench, and its journey ends there.

This cycle of waste isn’t just an environmental problem—it’s an economic one. This is why smart sortation is so important; batching plastic by grade and use, enabling extended lifespans and enhancing the circular economy.

“Our partnership with Pellenc ST marks a significant milestone for circularity. By combining our UV watermark technology, powered by GS1 standards, with their smart sorting and quality control solutions, we are giving brand owners unparalleled insight into their recycled packaging, reinforcing sustainability and traceability in the value chain.”

Alice Rackley, Chief Executive Officer

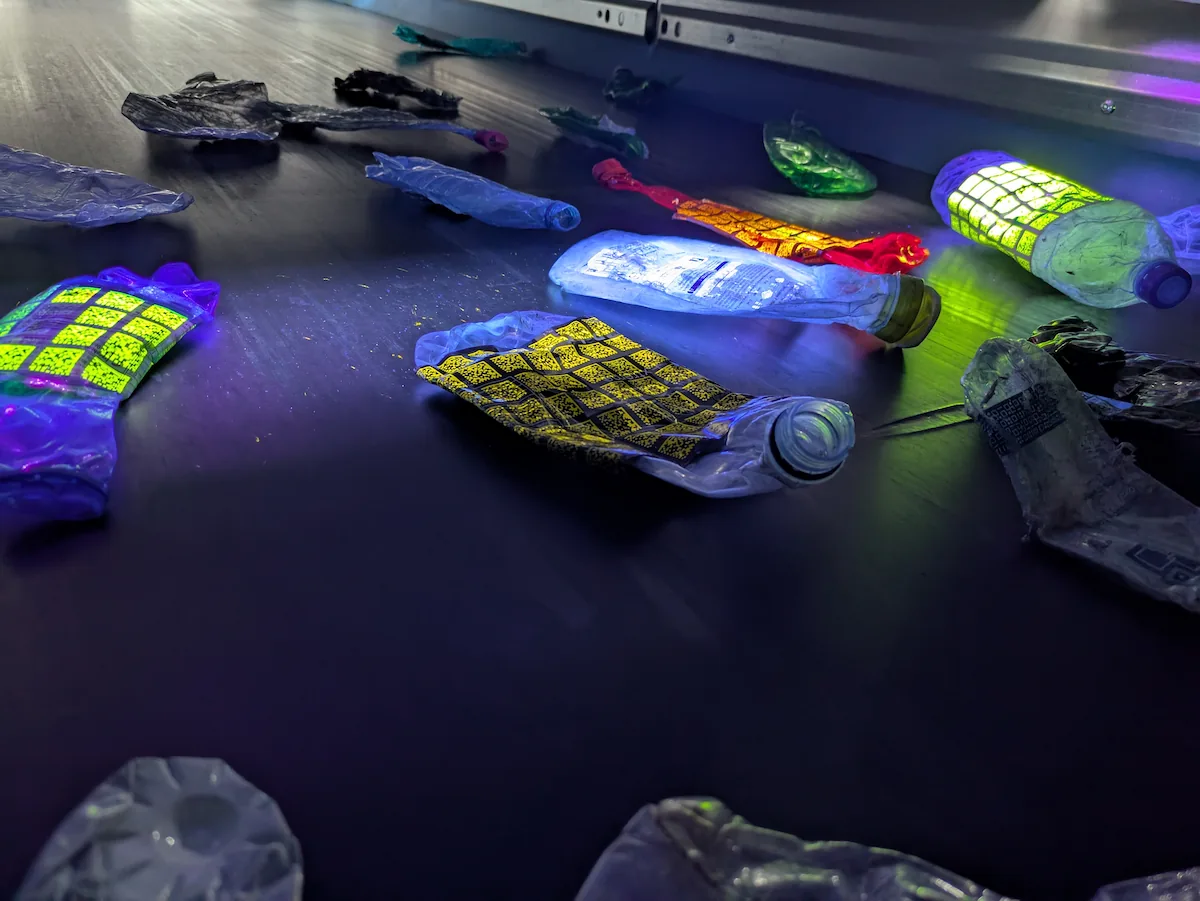

Packaging with UV tags scanned at a recycling centre.

Polytag kit is easy to install in recycling centres (MRFs).

Access accurate recycling data for the first time with Polytag.

Polytag Your Packaging

Live packaging lifecycle data

Talk directly to consumers

Offer rewards and incentives

Future-proof your labels